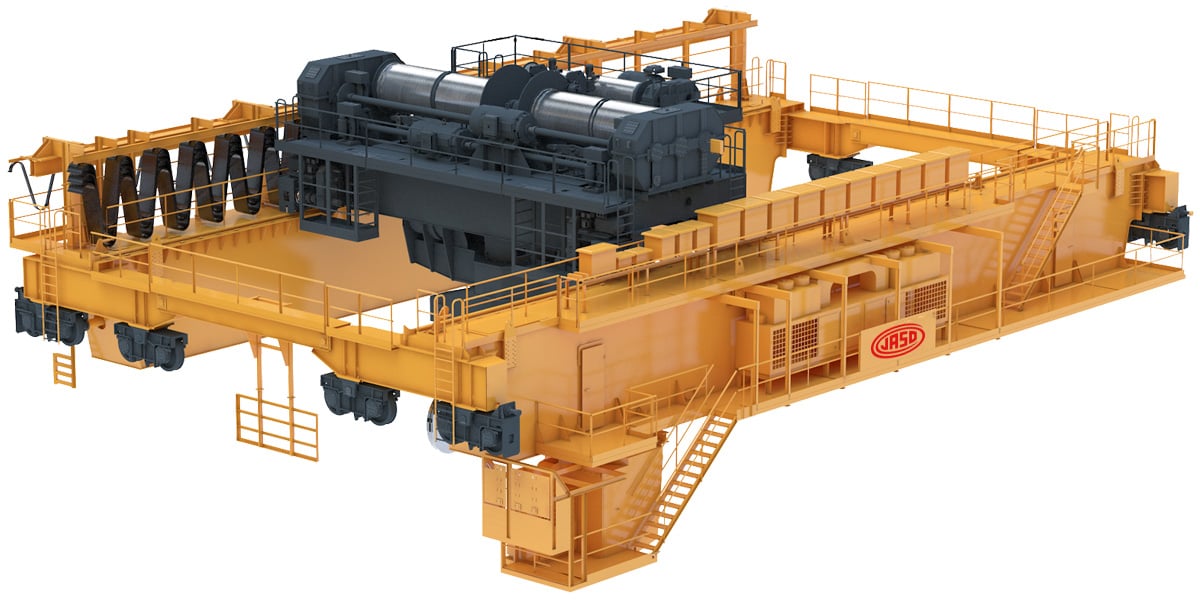

We carry out robust equipment sizing in order to offer security and reliability as well as a considerable reduction in maintenance costs due to the unification of elements and spare parts. Our specialised cranes are mainly designed for the steel, energy and general manufacturing sectors.

JASO Industrial Cranes uses the most advanced technology developed for the most demanding operations. Our capacity for innovation and design makes our cranes the most reliable machines on the market.

Emergency brake consisting of a brake disk independent of the drum in order to prevent the load from falling in the case of a double fault in the main lifting mechanism.

CloseA redundant double kinematic chain in the main hoist, with two motors, two planetary gears and four service brakes. In the case of a motor failure, the hoist can operate to full capacity and at half speed in the same work group. In the case of an emergency (a gear failure) the hoist can operate to full capacity using only one gear.

CloseFour cable sections that ensure that the load will not fall due to the breakage of one cable and that the carrier beam with the load remains stable.

CloseTwo independent groups for redundant trolley transfer. In the event of an emergency, the trolley is able to operate at full capacity with only one motor.

CloseProtection against heat hazards for the beam with the electric control gear, for the cabin and for the trolley.

CloseFour independent groups for the redundant overhead transfer situated within the beams. In the case of an emergency, the overhead crane operates at full capacity using half of its motors.

CloseElectronic equipment situated within the main beam, well protected and isolated. Dual system of redundant industrial air conditioning capable of operating with only one system in the case of an emergency.

CloseForged steel wheels with surface treatment mounted on runners using bracket tie-plates, with clearing plates and anti-derailment plates.

CloseCabin with reinforced glass to protect against molten steel splashes. Well protected and isolated, with an industrial air conditioning system.

CloseProtection against heat hazards for the beam with the electric control gear, for the cabin and for the trolley.

Close